Imagine you're about to print a batch of marketing brochures for an upcoming event. You've spent countless hours perfecting the design, ensuring every detail reflects your brand's identity. But when you receive the printed brochures, the colors are off, and your carefully chosen hues look nothing like they did on your screen. This scenario is all too common and can be incredibly frustrating. The culprit? A lack of understanding of the CMYK color model.

At STPT, we've encountered this issue numerous times in our nearly 40 years in the printing industry. Many people aren't familiar with CMYK, what it stands for, and its crucial role in printing.

That's why we're here to shed light on this important topic. Color is a surprisingly complex concept that can get very technical very quickly. But don’t worry, we’ll keep things simple. Today, we'll answer some pressing questions about CMYK, explain how it differs from other color models, and discuss why it's vital for achieving the best print quality.

What Is CMYK?

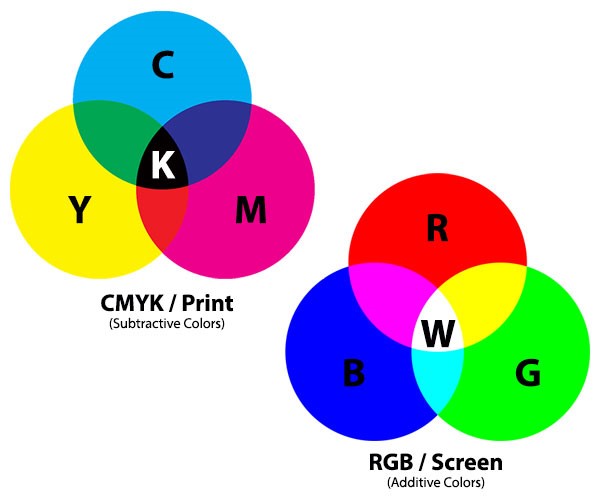

CMYK refers to the four colors of toner or ink commonly used in color printing: Cyan, Magenta, Yellow, and Key (Black). This color model is known as a subtractive color model, meaning colors are added to a white background to remove other colors from the visual field. Each layer of ink or toner subtracts the amount of white you see to create a specific color. This process is also known as process color printing. When you combine equal amounts of Cyan, Magenta, and Yellow, you get black.

To give you an example of how the CMYK model works, think about the process of printing a document. When you start the printing process, the paper is completely blank. Once you click print, the CMYK color model works to create the finished copy.

What Does the 'K' in CMYK Stand For?

In CMYK, 'K' stands for Key or key printing plate, which represents black. We stated earlier that when you mix C, M, and Y together, you get black. However, it’s not a true black, but rather a dark brown. To compensate, the CMY color model adds K or black to ensure deeper shadows and details in printed images, enhancing the overall quality.

Comparing CMY to RBY

The CMY (Cyan, Magenta, Yellow) color space is similar to the RBY (Red, Blue, Yellow) color model you most likely learned about in primary school. Both color wheels are comprised of three primary colors, which you can mix to create a variety of other colors. However, when it comes to color range and vibrancy, CMY provides a greater range and richness than RBY.

CMYK is optimized for printing, while RBY is often used in painting and art education. Despite their differences, both subtractive color models are valid and the choice to use either is entirely dependent on your needs and goals.

What Is RGB?

The RGB color model stands for Red, Green, and Blue. This color wheel originates from the way human vision perceives light and color. Unlike CMY and RBY, RGB is an additive color model. This means colors are added to a black background to create an image.

This model is used primarily for digital screens, such as those on your computer, phone, or TV.

Comparing RGB and CMYK

RGB and CMYK differ fundamentally, but they work hand in hand. RGB is an additive color model used to mix light, while CMYK is a subtractive color model used to mix solid pigments or dyes. In other words, RGB creates colors by adding light to a black background. Conversely, CMYK starts with a white background and subtracts light to create the final image. Both color wheels are opposites of each other (for example, cyan is the opposite of red), and each can achieve colors that the other can’t.

See the graphic below by Instantprint to see a graphical representation of the differences between CMYK and RGB:

Another way to remember the difference between RGB and CMYK is this:

- CMYK is used for printed materials, while RGB is used on your phone or computer screens.

Understanding the differences between CMYK and RGB is crucial in printing, especially for production or commercial printing. Printing a file in RGB instead of CMYK can result in a finished product with inconsistent or inaccurate colors. This can lead to costly reprints and frustration.

Safe to say, the CMYK color model can be a significant element to printers. Let’s expand on that point more in the next section:

Why is CMYK Important to Printers?

So, we’ve established that CMYK is used for printers, and RGB is what your computer screen uses. But, why, and how does a printer use the CMYK color model to produce documents?

Most printers use the CMYK color model because it produces the most consistent and accurate results for color printing. By combining different amounts of CMYK ink or toner, depending on the type of printer you have, a printer can create a wide variety of colors. This is usually done in dots per inch or DPI, which measures the resolution of a printed image. The higher the DPI, the more detailed and sharper your images.

In CMYK printing, laser printers use toner to create dots of color, while inkjet printers use ink.

When we edit digital files on our computer or phone screens, we see them in RGB. The images and photos we see on our screens are in RGB, but the finished printed product uses CMYK. The conversion from RGB to CMYK is necessary because printers work with inks, which blend differently than digital light.

How RGB Converts to CMYK

When preparing a document for printing, the RGB color space must be converted to CMYK. This conversion ensures that the colors seen on your screen closely match the printed output. Most photo editing software, like Photoshop, allows you to preview images in CMYK color mode, providing a more accurate representation of the final print.

The Conversion Process: Converting RGB to CMYK involves translating the light-based colors (RGB) into ink-based colors (CMYK). Software algorithms analyze the RGB values of each pixel and convert them to corresponding CMYK values. This process takes into account the different color gamuts of RGB and CMYK, adjusting the hues to maintain color fidelity as much as possible. For instance, vibrant colors in RGB may appear less saturated in CMYK due to the narrower color range of inks.

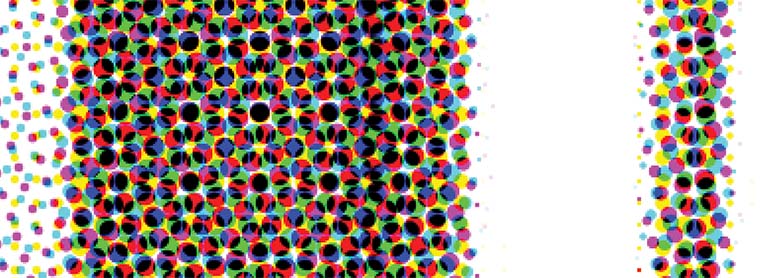

Understanding Halftones

Halftones are used in printing to create the illusion of depth and range in color tone. Both inkjet and laser printers use halftones by varying the size and spacing of dots to represent different shades of color. This technique is essential for producing detailed and high-quality images. Higher-end printers will give you greater precision and allow the dots to be even smaller.

Why Does CMYK Matter to You?

If you work in an industry where precision and high quality are crucial, understanding CMYK is essential. Knowing how your image will appear before printing can help you avoid costly errors.

Keep in mind that there will always be slight changes when converting from one color model to another, particularly during the printing process. For the most accurate conversion from RGB to CMYK, it's best to manually make the conversion using editing software like Photoshop. Software programs like this also allow you to preview (soft proof) your images in CMYK color mode before you print. This helps provide a more precise representation of your final print.

Humans, screens, and printers process color differently. Understanding key color models like CMYK and RGB is crucial for accurately translating your digital vision to the finished printed product.

Are You a Fit for a Production Printer?

Production printers are primarily used to carry out mass print jobs or handle the printing of specialty media, like brochures and posters, where you would need to have color consistency-- which CMYK is a big part of.

How do you know if you’re a fit for a production printer? Here are three categories of workgroups that might be a candidate for a production printer:

- Businesses that have a daily need to make specialty prints, like booklets and manuals, at a high print volume, which can be anywhere from 50,000 pages per month to over a million.

- Businesses that require special print finisher options for booklets and other specialty prints.

- Businesses that desire advanced color technology and image quality enhancements for their finished prints.

Production printers are mainly for in-plant print shops or organizations that need to print on specialty media frequently.

Numerous options for production printers are available on the market. For example, Xerox, whose products we sell, has entry-level and advanced production printers.

Here is an image of an advanced production printer, The Xerox Iridesse Press:

This production printer can also use CMYK+, which allows you to create metallic and fluorescent colors along with gold and clear. Learn more about how CMYK+ works in our dedicated blog.

There are also plenty of other printer brands that sell production machines for workgroups with varying goals. Vetting out your options is always recommended, especially when it comes to production printers that can run well into the hundred thousand-dollar range.

Read our blog on production printers to learn more about them and whether investing in one might be right for you.

Ensuring Print Quality: Your Next Steps

CMYK plays a central role in the color printing process. When your business relies on high-quality color prints, it’s crucial to understand and utilize CMYK.

Ready to enhance your printing experience? Contact us today to schedule a consultation or learn more about our quality yet affordable toner offering: Xerox Everyday Toner.

If you have high-volume printing needs, ask us about our advanced production-level digital printing presses. Let us help you optimize your office productivity and manage your printing costs effectively.